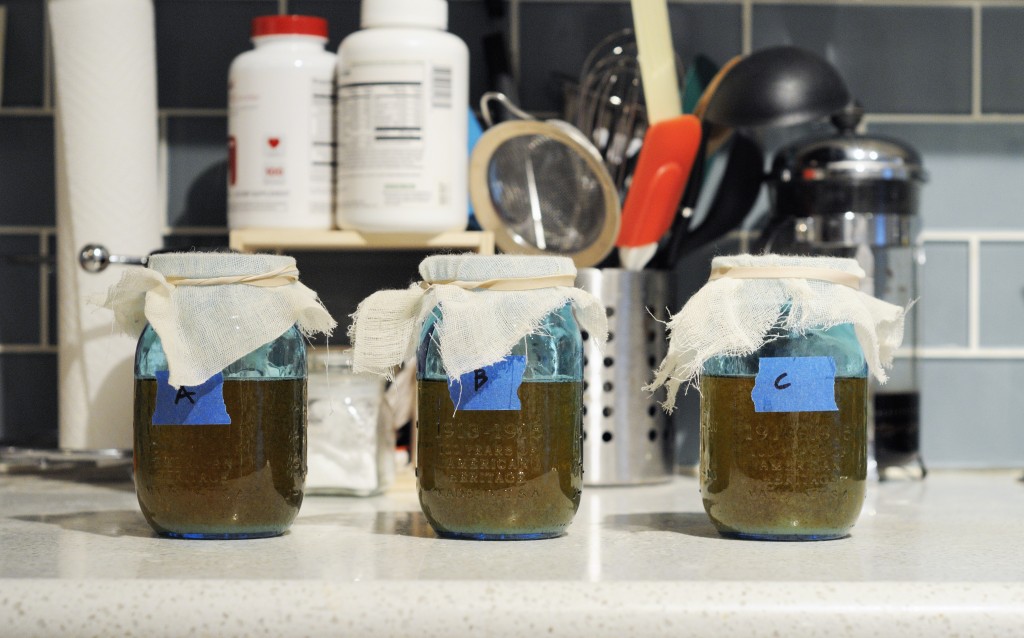

The somewhat laborious process of maintaining mixed cultures via what I’ve called, for lack of a better name, my Bioreactor Project is beginning to bear fruit (or in this case, sour beer). The recipe and review below represents the second generation fermentation of mixed culture “A” grown up from the following beers:

- Cantillon Gueuze

- Tilquin Gueuze

- Russian River Beatification

- Crooked Stave Surette

- Jolly Pumpkin La Roja

I’ve managed to consistently maintain the bioreactor on a 4-month refresh cycle. The results so far have been positive, although I’ve noticed that the fermentations have rather sluggish starts, which is a bit concerning. If I were to implement this program on a commercial level, I would decrease the refresh cycle to something more reasonable, perhaps refreshing every couple months. Unfortunately, the practicality for doing this at a homebrew level is somewhat limited (at least for myself).

For this iteration of the recipe, I wanted to see how the souring culture might synergize (or clash) with a slightly toasty malt background. Vienna malt plays a prominent role in the beer bringing a subtle toasty note to what should be a fairly funky sour beer.

Specifications:

Size: 1.25 gal

Efficiency: 66%

Attenuation: 85%

Original Gravity: 1.054

Terminal Gravity: 1.014

Color: 11.13 SRM

Alcohol: 5.25% ABV

Bitterness: 0 IBU

Terminal pH: 2.60

Malt Bill:

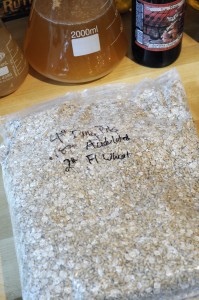

2.75 lb (91.7%) Weyermann Vienna Malt

0.25 lb (8.3%) Weyermann Carared

Mash Profile:

160°F – 60m

Water Treatment:

Extremely Soft NYC Water

Added to mash: 2g Calcium Chloride

Hopping:

0.25 oz Aged Cascade Hops (0.0% AA) – 90m

Kettle Additions:

0.25 ea Whirlfloc Tablets (Irish moss) – added during boil, boiled 15m

0.25 tsp Wyeast Nutrient – added during boil, boiled 10m

Yeast:

Bio Reactor “Culture A” – racked from a 4-month old fermentation using the same culture

Tasting Notes:

Judged as a BJCP 28B Mixed Fermentation Sour Beer

Aroma (8/12):

Prominent pie cherry, fruity Brett aromatics on the nose with a punchy level of lactic sourness. There is a nice soft, bready malt nose featuring light toast along with some oxidized dark fruit (think prune). Some of the more funky Brett aromatics of wet hay and earth are subtle, offering background complexity. As the beer warms, the beer exudes a nutty, almost Amaretto-like aroma.

Appearance (0/3):

The beer strikes a deep copper tone with light chill haze. A vigorous pour offers up a very slight white foam that quickly dissipates. The beer is a bit under-carbonated, making head formation a difficult task. Also not helping matters is lactobacillus’ ability to degrade foam positive proteins.

Flavor (12/20):

The beer strikes a medium acidity, primarily lactic in nature although a touch of acetic acid is perceptible. The first sip reveals a prominent THP flavor that is reminiscent of Cheerios, which is actually quite pleasant when tasted in concert with the lightly toasty Vienna malt base. There is a low level of residual sweetness which helps take the edge off of some of the stronger acetic acid notes. Interestingly, when tasted at 4-months old, the beer had a fairly robust plastic-like phenol which seems to have been transformed at this point into other more positive flavors.

Mouthfeel (1/5):

The beer has a medium to medium-light body with a very low carbonation level. The beer is in desperate need of something to lift it off the palate; a task that the acidity only marginally accomplishes.

Overall Impression (6/10):

The beer falls a bit flat, but does offer up some interesting complexity, particularly in the commingling of some of the THP and toasty Vienna malt characters. The touch of oxidized malt flavor plays nicely with the Brett fruitiness—something that I think could become even more interesting if actual fruit (think tart pie cherries) were introduced into the mix.

Good (27/50)